Polishing-service

Level 1 standard

Natoli professional polishing Kits

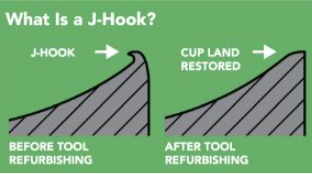

Punches and dies experience a lot of wear during tablet production, leading to tooling issues like J-Hook scratches and abrasions, tip had heat wear, and burred edges.

A well-structured polishing program coupled with correct tool polishing equipment will extend tool life, decrease press downtime, and increase high-quality tablet yields by restoring punches and dies to like-new condition.

Choosing appropriate polishing equipments critical for an effective tool maintenance program. Many times, equipment selection is limited to an authorized budget. Unfortunately, most companies will save more in the long run versus noticeable immediate saving. Due to budgetary constraints, things to consider when making your selection are 1. The quantity of tool sets required to the polished. 2. footprint of dedicated maintenance program space available and 3. Proper training, it is also beneficial to calculate growth for future budget and needs.

Before making your final equipments choices talk with Natoli representative to discuss the benefits and features of each level.

About level 1 Standard Polishing

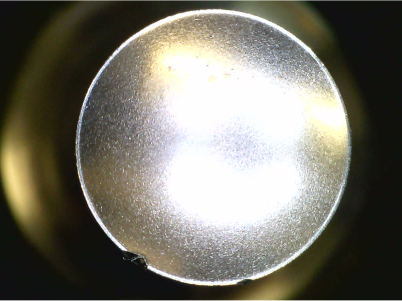

Help eliminate tableting issues like picking and sticking with the Level 1 Standard Polishing Kit. This polishing kit is crucial parts of maintaining punch cups. As cups lost luster they become more likely to cause tableting issues. This hand polishing kit allows you to return the luster to your punch cups, keeping tools in working order and producing longer, while minimizing downtime.

Procedure

Used heavy-duty Workwipes for initial punch cleaning to wipe away oils and product residue. Follow by measuring punch's working length (top of punch head to the deepest area of punch cup) before polishing as tablet quality can be affected if lower punches are inconsistently polished. Lover punches must maintain the same overall length within a set to ensure proper ejection from tablet press.

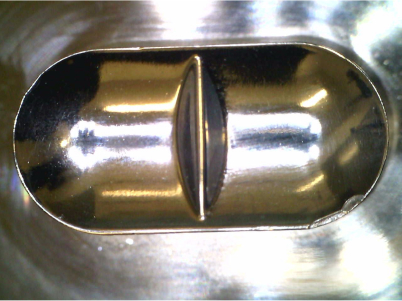

Measure punch working length using the Digital Indicator while holding punches in place whit “B” or “D” type Punch Holders. Use the Handheld Magnifier to inspect for burred edges, tip wear, abrasions and embedded product.

Clean product form embossed punch cup using “6” Embossing Peck. Polish non-embossed punch cups with the Motorized Hand Polisher using Felt Bobs with either the White Rouge Bar or Home Gloss Bar Polish embossed punch cups using Fine Dental Brushes with either Diamond Compound or Polishing Paste.

Finish by repeating punch working, length measurement with Digital Indicator and cleaning punches with Workwipes.

Level 2 advanced

Used heavy-duty Workwipes for initial punch cleaning to wipe away oils and product residue. Follow by measuring punch's working length (top of punch head to the deepest area of punch cup) before polishing as tablet quality can be affected if lower punches are inconsistently polished. Lover punches must maintain the same overall length within a set to ensure proper ejection from tablet press.

Measure punch working length using the Digital Indicator while holding punches in place whit “B” or “D” type Punch Holders. Use the Handheld Magnifier to inspect for burred edges, tip wear, abrasions and embedded product.

Clean product form embossed punch cup using “6” Embossing Peck. Polish non-embossed punch cups with the Motorized Hand Polisher using Felt Bobs with either the White Rouge Bar or Home Gloss Bar Polish embossed punch cups using Fine Dental Brushes with either Diamond Compound or Polishing Paste.

Finish by repeating punch working, length measurement with Digital Indicator and cleaning punches with Workwipes.

About advanced polishing

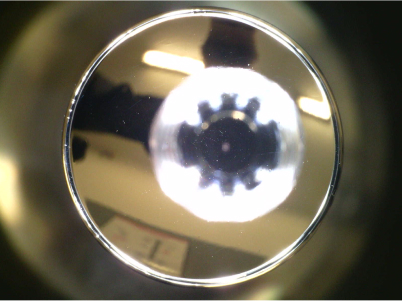

The Level 2 Advanced Polishing Kit lets you polish like the experts and features the Complete Stainless Steel Polishing Station. Self-contained and moveable the Polishing Station features a 3/4 hp polishing motor and 18-gauge stainless steel cabinet base.

This kit is an absolute must for maintaining and polishing the entire punch body. Remove J-hook burrs easily restore land to punch tips and bring back a mirror-finish to punch cups in one easy steps reducing tableting issues like chipping picking and sticking. This is the only method to achieve these critical punch maintenance and polishing steps at one time.

This full-cabinet system includes, stainless steel cabinet, a buffing motor, vacuum system with filters, buffing wheels, and Led Light.

What is J-hook?

Refurbishing punch cups with the “10” unsewn buffing wheel eliminates J-hook, the leading cause of capping lamination and poor friability. If detected early. J-hood cam be easily and quickly be repaired. A large unsewn cotton buffing wheel or deburring stone effectively eliminates J-hook and restore land to punches.

Procedure

The Level 2 Advanced Polishing Kit lets you polish like the experts and features the Complete Stainless Steel Polishing Station. Self-contained and moveable the Polishing Station features a 3/4 hp polishing motor and 18-gauge stainless steel cabinet base.

First wipe tooling off using the Heavy-duty Work Wipes at the tablet press to reduce contamination.

Transport and keep punches secure at the workstation with the Punch holding Trays. Use Rectangle LED Magnifier to quickly inspect for visual imperfections.

If necessary, remove product from embossed punch cups with 6” Embossing Pick. Measure punch working length (from top of punch head to the deepest area of the punch cup) using the Digital Indication, holding punches in place with “B” or “D” Punch Holders.

Polish punches using the Stainless Steel Polishing Station with buffing wheel to polish entire punch, restore land to punch cups, and revitalize punch'a mirror-like finish. The Motorized Hand Polished, Fine Dental Brushes, and Polishing Paste can be used to help restore embossed cups.

Lightly remove excess polish from punch cups with Heavy-duty Workwipes and check a final time for proper working length tolerance with Digital Indicator.

Before/After